Material Investigations | Betts Metal AgAIN Silver

Offering responsibly sourced gold in all of The Betts Group manufactured gold products is part of their industry-leading commitment to supply responsibly mined gold to investors and the jewellery trade. In addition to offering Single Mine Origin (SMO), Fairmined and Fairtrade gold products, AgAIN silver is a traceable silver product now available. We asked Charlie Betts, managing director of The Betts Group to share more about the AgAIN Silver product.

This post is part of our Material Investigations: Gold series that investigates options for sourcing traceable gold through Q&A style articles. As this is one of the few traceable silver products commercially available, we made the decision to include this supply within the Gold series, despite not being a gold product. The Scottish Goldsmiths Trust does not verify any of the claims made by interviewed suppliers but instead aims to introduce diverse types of traceable gold available to purchase, allowing you to make further enquiries to inform your metal sourcing. For more information read the series introduction below:

What is AgAIN silver?

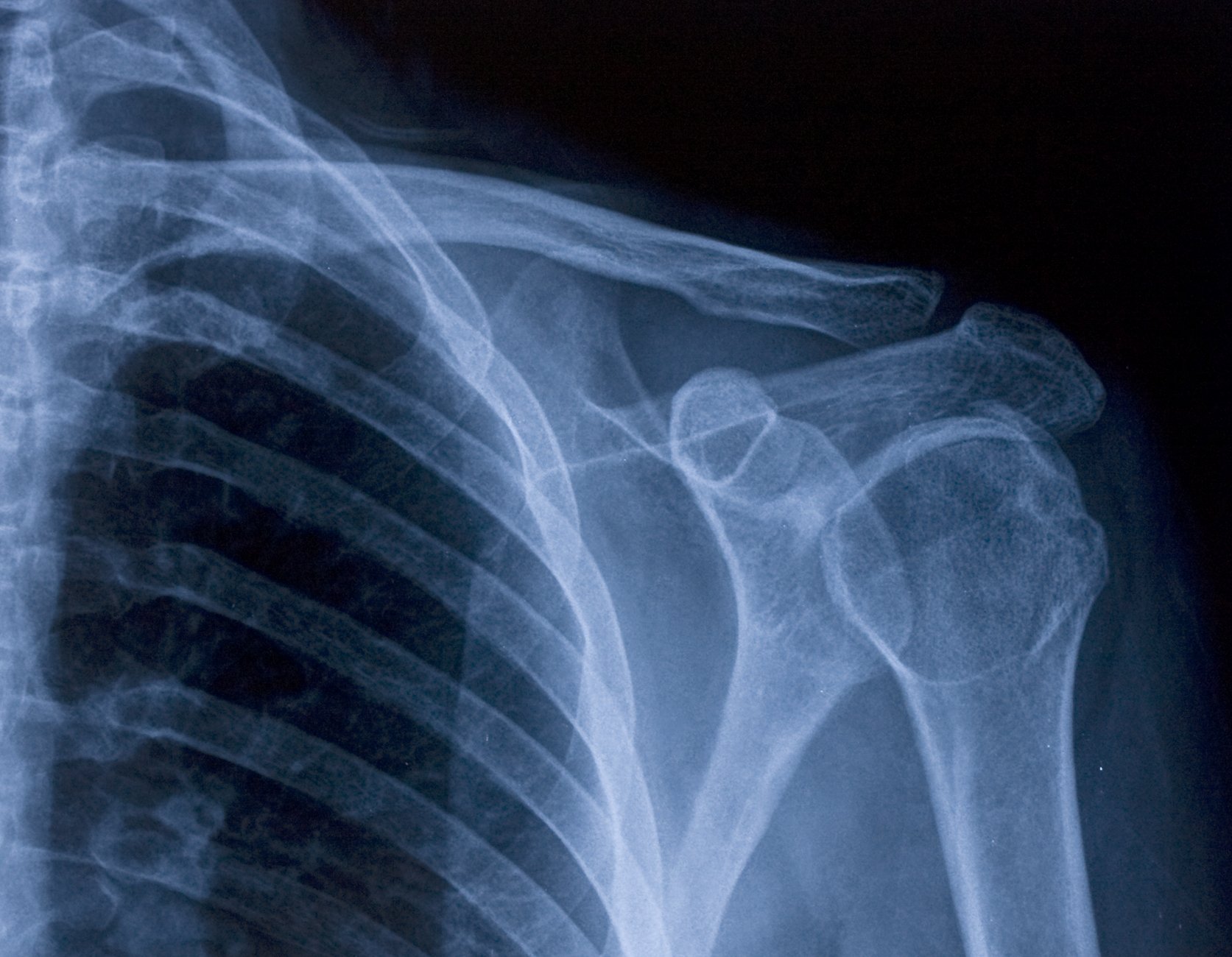

AgAIN silver is a sustainable, traceable metal created from recycled medical X-ray films. Every stage of this process takes place here in the UK – this video shows how it works:

This silver helps hospitals to earn a financial rebate from old X-rays – previously, many hospitals were paying a fortune to store film beyond its legal retention date or send it to landfill. AgAIN also provides customers with a fully traceable and sustainable silver supply. Every element of the X-ray is recycled, further minimising AgAIN’s carbon footprint.

Could you outline how Betts established this supply chain with the NHS?

The Betts Group has been working with the NHS and NHS partners for decades in relation to precious metal wastes. Silver is contained in X-Ray film but because of its anti-bacterial properties it also has other applications within healthcare, such as in wound dressings. When silver-bearing medical products go beyond their shelf-life, the Betts Group is well placed to recover silver from such products, generating a financial return for trusts.

Because the NHS operates as a large number of individual trusts, our supply chain relationship varies. Some larger film jobs are won through open commercial tenders, others through commercial negotiation directly with trusts or NHS storage partners looking to maximise efficiencies.

How do you certify the process? Which third-party(s) are auditing the process?

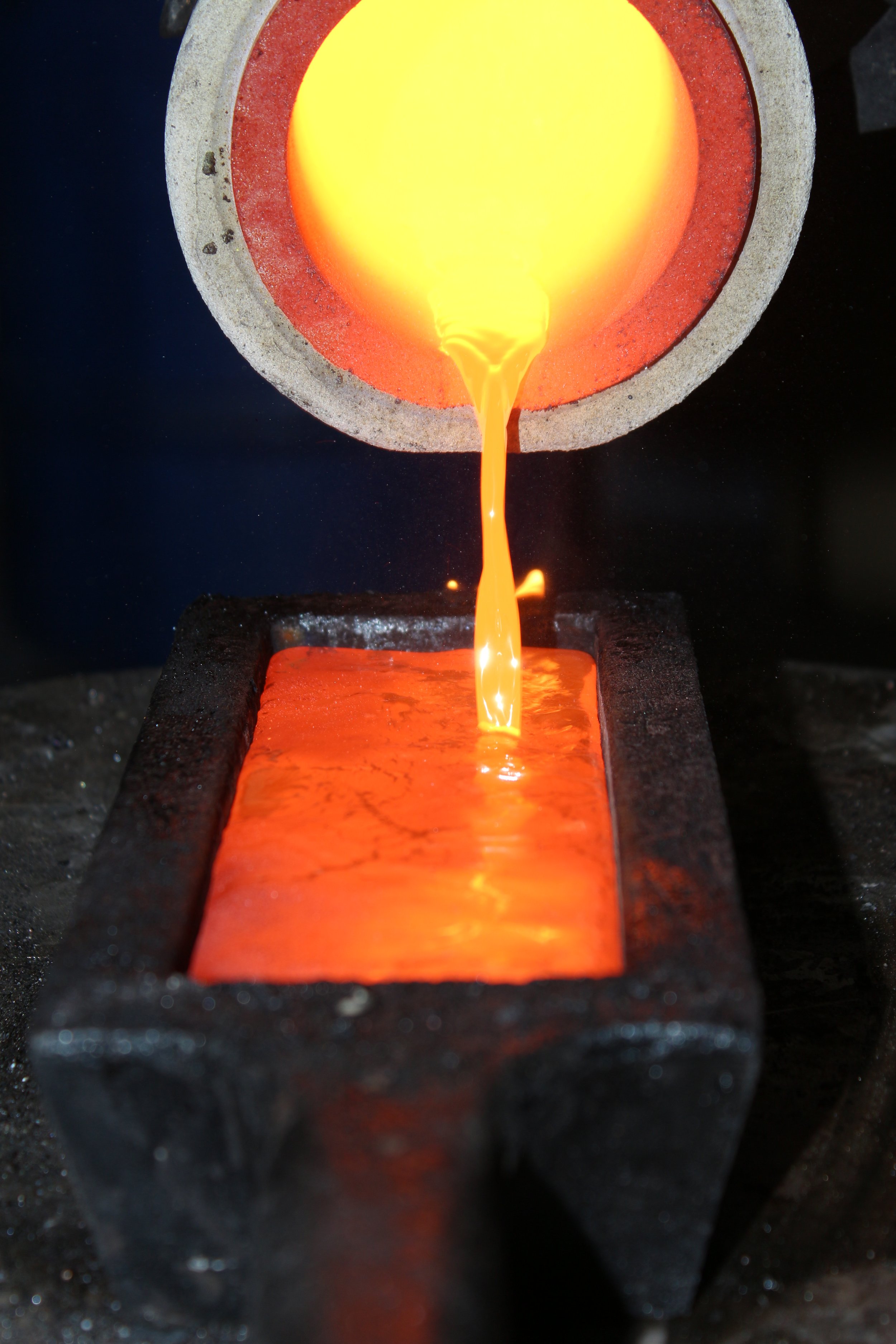

The Betts Group initially established a robust chain of custody for AgAIN silver internally. This involved retaining detailed, auditable records of all X-Ray film sources, segregating the film as it was prepared for processing and then processing batches of medical X-ray film in segregation from other x-rays. Even through the smelting and refining processes, total segregation is maintained to ensure AgAIN silver is not contaminated with any other material. This means separate crucibles are used in melting processes, a totally segregated electrolytic cell is dedicated to refining AgAIN silver and all product manufacturing also happens in segregation. As the Betts Group is highly experienced in working with segregated material (such as Fairtrade, Fair Mined and SMO gold), our Buxton site is geared around this kind of manufacturing process already.

As longstanding members of the RJC, we felt this was the logical partner to audit and certify this process. RJC performed this function and certified AgAINs chain of custody claims in 2022.

How might buyers assure their clients of the material provenance? E.g. Do you intend to develop a certification hallmarking system for buyers of this metal?

This silver comes with a QR code outlining where the metal has been sourced from and transparently detailing the process. Jewellers can pass this QR code on to their customers. We do not have plans to create an AgAIN hallmark in the immediate future as we currently only certify AgAIN silver to the point of delivery to jewellers.

What would you consider are the key distinctions of AgAIN silver, in comparison to other traceable products?

Recycled silver is widely available, but it’s rare that it can be traced to a known source. This means metal which has been recently mined or come from problematic sources (eg Russia, conflict areas etc) can very easily find its way into the supply chain. Medical X-Ray film is a waste product that was previously going to landfill or being incinerated. Unlike other silver that was already being recycled, AgAIN silver represents a genuine sustainability gain.

Customers can have real confidence that AgAIN represents a sustainable, conflict-free option. As every stage of the silver recycling process takes place in the UK, it also benefits the British economy.

How has this commitment been received so far, by customers and your NHS collaborators?

The reception for AgAIN has been very positive indeed; so much so that the vast majority of our capacity is already accounted for by major partners such as The Royal Mint, Sheila Fleet and Vipa Designs. We have still ensured that we continue to retain capacity to supply smaller designers and craftspeople and find it encouraging to see early-career jewellers such as Meghan Griffiths of Angharad prioritising responsible sourcing by adopting AgAIN.

Lastly, where can customers order AgAIN silver and/or have it manufactured?

Customers can order AgAIN silver casting grain on the Betts Metal Sales website. We can currently manufacture sheet and wire from AgAIN to order, but intend to introduce this as a stock item in due course. Jewellers can also contact Vipa Designs to discuss casting options in AgAIN.